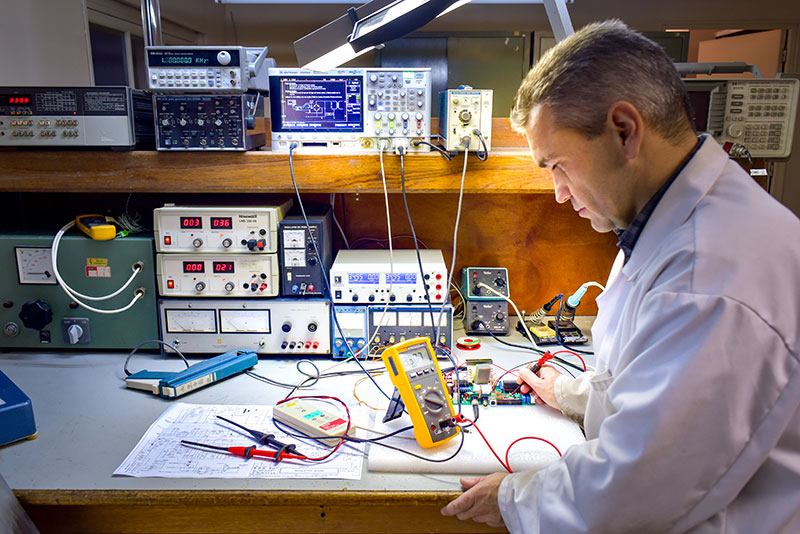

Proven processes for quality material!

For the past 10 years, E.D.N. has been designing customized power supply modules and energy converters for industry sectors, medical and aesthetic sciences, professional lighting and environment. In order to best meet our customer requirements, we have developed a qualitative process ranging from co-writing specifications to production in small and medium-sized series.